Electroplating Barrels

Product Details:

Electroplating Barrels Price And Quantity

- 01 Piece

- 01 INR/Piece

- 1.00 - 1.00 INR/Piece

Product Description

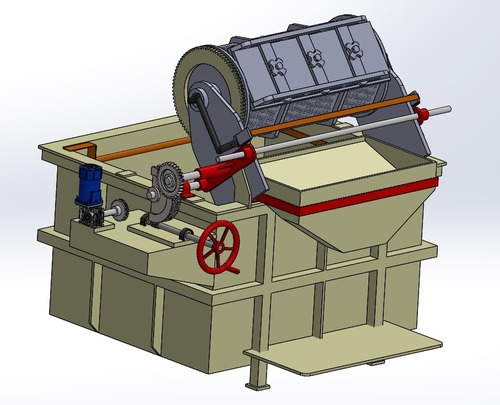

Electroplating Barrels

Description:

Electroplating barrels are specialized equipment designed for the efficient and effective electroplating of small to medium-sized metal components. These barrels facilitate the immersion of parts in plating solutions, allowing for uniform coating and enhanced process control. Constructed from high-quality materials, our electroplating barrels are engineered to withstand harsh chemical environments while delivering consistent performance.

Technical Specifications:

-

Material: Typically made from Polypropylene (PP) or Polyvinyl Chloride (PVC) for excellent chemical resistance.

-

Capacity: Available in various sizes, accommodating loads from 10 kg to 100 kg, depending on your production needs.

-

Design Options: Available in open or closed designs, with options for perforations to facilitate uniform plating and draining.

-

Chemical Resistance: Resistant to a wide range of acids and alkalis commonly used in electroplating processes, ensuring longevity and reliability.

-

Temperature Tolerance: Can withstand operational temperatures up to 80C, depending on the material.

-

Motorized Options: Equipped with rotating mechanisms to ensure even distribution of plating materials and reduce shadowing effects.

Industrial Standards:

Our electroplating barrels are manufactured in compliance with recognized international standards, ensuring quality and safety in operations:

Applications:

Electroplating barrels are ideal for:

-

Plating of Small Parts: Perfect for components such as fasteners, automotive parts, electronic connectors, and decorative items.

-

Batch Processing: Suitable for high-volume production runs where efficiency and consistency are essential.

-

Various Plating Processes: Compatible with processes such as nickel plating, chrome plating, and gold plating.

FAQ

Q1: What is the primary function of electroplating barrels?

A1: Electroplating barrels are designed to coat small to medium-sized metal components uniformly with a layer of metal through the electroplating process.

Q2: What materials are electroplating barrels made of?

A2: Our barrels are typically constructed from materials like Polypropylene (PP) or Polyvinyl Chloride (PVC), both known for their excellent chemical resistance and durability.

Q3: How do you ensure the quality of electroplating barrels?

A3: Our barrels adhere to stringent manufacturing standards, including ASTM D4101 and ISO 9001, and undergo rigorous testing to ensure they can withstand harsh chemical environments and operational conditions.

Q4: Can the size of the electroplating barrels be customized?

A4: Yes, we offer customization options to meet specific size and capacity requirements, accommodating various production needs.

Q5: What maintenance do electroplating barrels require?

A5: Maintenance is minimal; however, regular inspections for wear and tear, along with cleaning after each use, will help prolong the life of the barrels.

Q6: Are electroplating barrels suitable for high-volume production?

A6: Yes, our electroplating barrels are designed for batch processing, making them ideal for high-volume production runs where efficiency and consistency are critical.

Q7: How do you handle environmental regulations regarding electroplating?

A7: We ensure that our electroplating barrels comply with environmental regulations, including RoHS compliance, to minimize hazardous substances in our manufacturing process.

Other Products in 'Electroplating Plant' category

GST : 33ABNCS5795F1ZU

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free